Waste reduction initiatives and circular economy

Source reduction

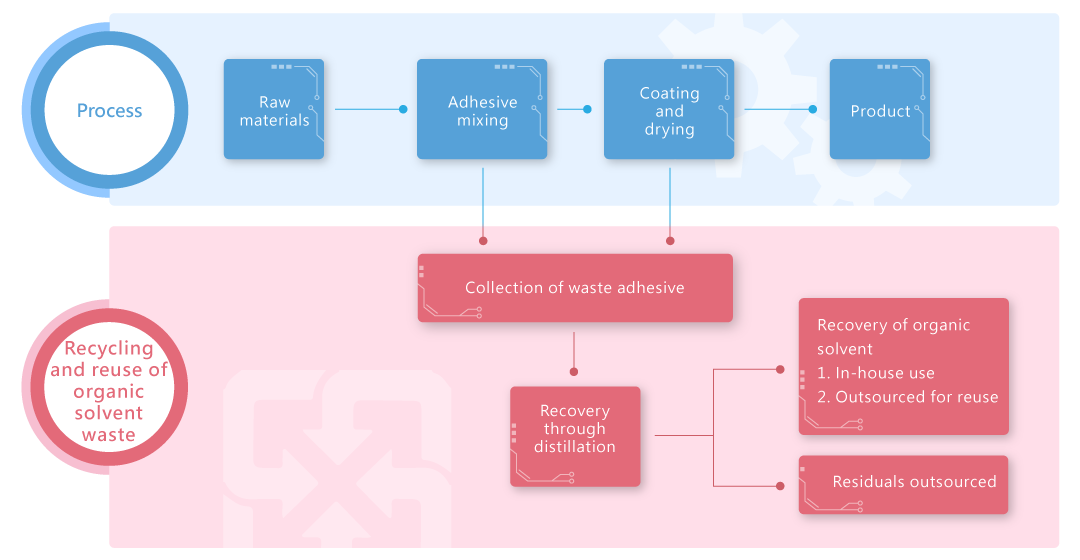

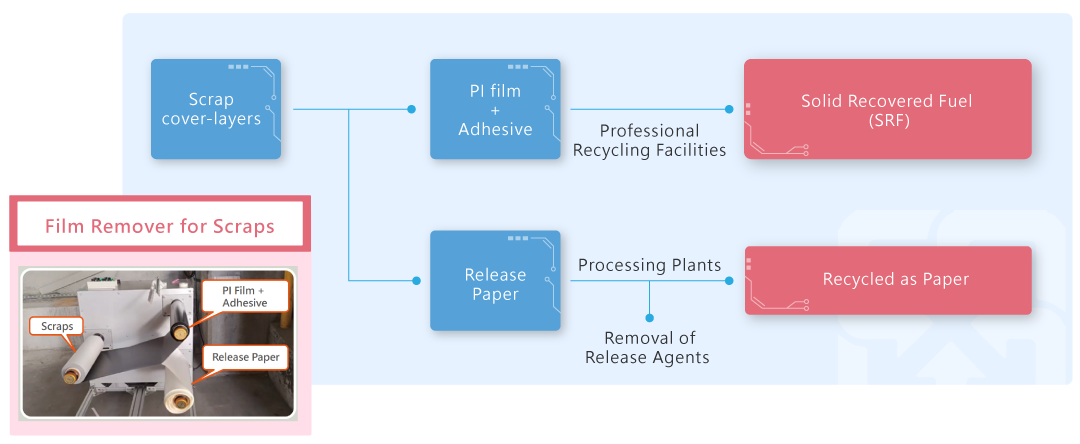

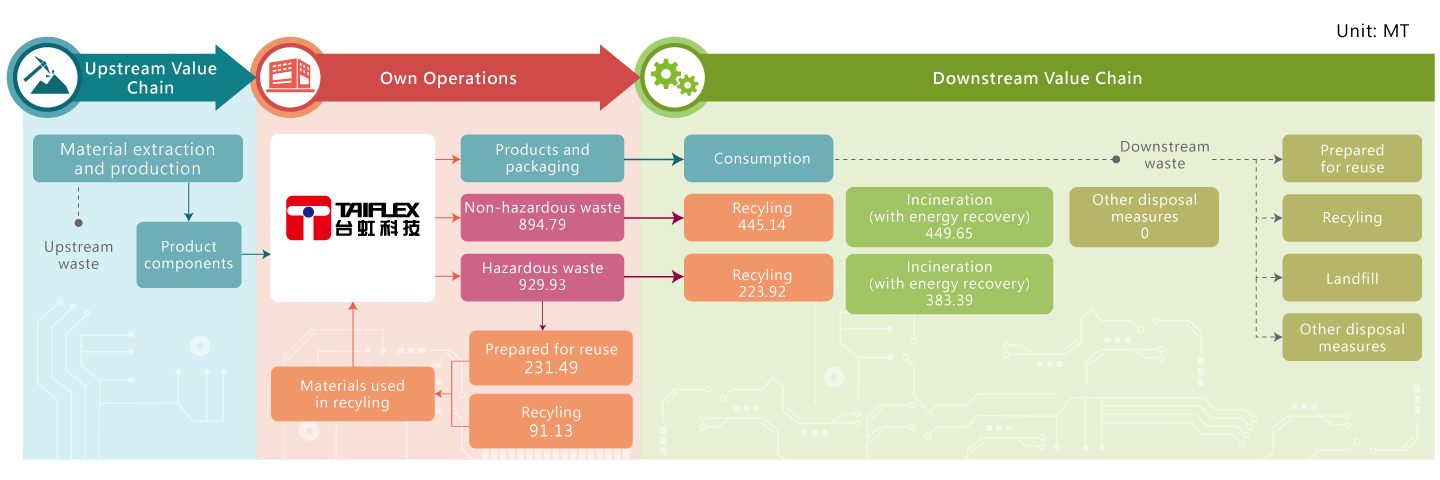

Taiflex is committed to zero waste. Besides promoting the concept of resource conservation to employees during daily operation, Taiflex focuses on process enhancement for source reduction. As we reduce the consumption of resources and materials, we also minimize the pollutants generated. For air pollution, wastewater, and solid waste which we cannot eliminate completely at present, we establish pollution control facilities or engage qualified professional companies to handle the matters. We strive to reduce the environmental impact of our operations and seek the best solution in order to gradually achieve the ultimate goal of zero pollution.